Manufacturing security hardening

Last time my colleague Ripa and I discussed about industrial UX and productivity. This time I focus on factory security especially in situations when factories will be connected to the cloud.

Historical habits

As we know for a long time manufacturing OT workloads were separated from IT workloads. Digitalization, IoT and edge computing enabled IT/OT convergence and made it possible to take advantage of cloud services.

Security model at manufacturing factories has been based on isolation where the OT workload could be isolated and even fully air-gapped from the company’s other private clouds. I recommend you to take a look at the Purdue model back from the 1990s, which was and still is the basis for many factories for giving guidance for industrial communications and integration points. It was so popular and accepted that it became the basis for the ISA-95 standard (the triangle I drew in a blog post).

Now with new possibilities with the adoption of cloud, IoT, digitalization and enhanced security we need to think:

Is the Purdue model still valid and is it just slowing down moving towards smart and connected factories?

Especially now that edge computing (manufacturing cloud) is becoming more sensible, we can process the data already at level 1 and send the data to the cloud using existing secured network topology.

Is the Purdue model slow down new thinking ? Should we have Industrial Edge computing platform that can connect to all layers?

Well architected

Thinking about the technology stack from factory floor up to AWS cloud data warehouses or visualizations, it is huge! It’s not so straightforward to take into account all the possible security principles to all levels of your stack. It might even be that the whole stack is developed during the last 20 years, so there will be legacy systems and technology dept, which will slow down applying modern security principles.

In the following I summarize 4 main security principles you can use in hybrid manufacturing environments:

- Is data secured in transit and at rest ?

Use encryption and if possible enforce it. Use key and certificate management with scheduled rotation. Enforce access control to data, including backups and versions as well. For hardware, use Trusted Platform Module (TPM) to store keys and certificates.

- Are all the communications secured ?

Use TLS or IPsec to authenticate all network communication. Implement network segmentation to make networks smaller and tighten trust boundaries. Use industrial protocols like OPC-UA.

- Is security taken in use in all layers ?

Go through all layers of your stack and verify that you cover all layers with proper security control.

- Do we have traceability ?

Collect log and metric data from hardware and software, network, access requests and implement monitoring, alerting, and auditing for actions and changes to the environment in real time.

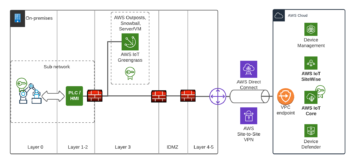

Secured data flow

Following picture is a very simplified version of the Purdue model aligned to manufacturing control hierarchy and adopting AWS cloud services. It focuses on how manufacturing machinery data can connect to the cloud securely. Most important thing to note from the picture is that network traffic from on-prem to cloud is private and encrypted. There is no reason to route this traffic through the public internet.

You can establish a secure connection between the factory and AWS cloud by using AWS Direct Connect or AWS Site-to-Site VPN. In addition to this I recommend using VPC endpoints so you can connect to AWS services without a public IP address. Many AWS services support VPC endpoints, including AWS Sitewise and IoT Core.

Manufacturing machinery is on layers 0-2. Depending on the equipment trust levels it’s a good principle to divide the whole machinery into cells / sub networks to tighten trust boundaries. Machinery with different trust levels can be categorized in its own cells. Using industrial protocols, like OPC-UA, brings authentication and encryption capabilities near the machinery. I’m very excited about the possibility to do server initiated connections (reverse connect) on OPC-UA, which makes it possible for clients to communicate with server without firewall inbound port opening.

As you can see from the picture, data is routed through all layers of and looks like layers IDMZ (Industrial Demilitarized Zone), 4 and 5 are almost empty. As discussed earlier, only for connecting machinery to the cloud via secure tunneling we could bypass some layers. But for other use cases the layers are still needed. If for some reason we need to route factory network traffic to AWS Cloud through the public internet, we need a TLS proxy on IDMZ to encrypt the traffic and protect the factory from DDoS attacks (Distributed Denial of Service attack).

The edge computing unit on Layer 3 is a AWS Greengrass device which ingests data from factory machinery, processes the data with ML and sends only the necessary data to the cloud. The unit can also discuss and ingest data from Supervisory Control and Data Acquisition (SCADA), and Distributed Control System (DCS) and other systems from manufacturing factories. AWS Greengrass uses x509 certificate based authentication to AWS cloud. Idea is that the private key will not leave from the device and is protected and stored in the device’s TPM module. All the certificates are stored to AWS IoT Core and can be integrated to custom PKI. For storing your custom CA’s (Certificate Authority) you can use AWS ACM. I strongly recommend to design and build certificate lifecycle policies and enforce certificate rotation for reaching a good security level.

One great way of auditing your cloud IoT security configuration is to audit it with AWS IoT Device Defender. Also you can analyse the factory traffic real-time, find anomalies and trigger security incidents automatically when needed.

Stay tuned

Security is our best friend, you don’t need to be afraid of it.

Build it to all layers, from bottom to top in as early a phase as possible. AWS has the security capabilities to connect private networks to the cloud and do edge computing and data ingesting in a secure way.

Stay tuned for next posts and check out our Connected Factory Kickstart if you haven’t yet

https://www.solita.fi/en/solita-connected/