Factory Floor and Edge computing

Happened last time

In the first part of this blog series I discussed the industry 4.0 phenomenon: Smart and Connected Factory, what benefits it brings, what is IT/OT convergence and gave a short intro about Solita’s Connected Factory Kickstart.

This part is more focused on the data at Factory floor and how AWS services can help in ingesting the data from factory machinery.

Access the data and gain benefits from Edge computing

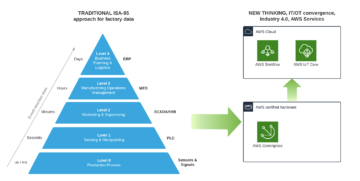

So what is the data at the Factory floor? It is generated by machinery systems using many sensors and actuators. See the following picture where on the left there is a traditional ISA-95 pyramid for factory data integrating each layer with the next. The right side represents new thinking where we can ingest data from each layer and take advantage of IT/OT convergence using AWS edge and cloud services.

PLC (Programmable Logic Controller) typically has dedicated modules for inputs and dedicated modules for outputs. An input module can detect the status of input signals like switches and an output module controls devices such as relays and motors.

Sensors are typically connected to PLC’s. To access the data and use it in other systems, PLC’s can be connected to an OPC-UA server. The server can provide access to the data. One traditional use case is to connect PLC to factory SCADA systems for high level supervision of machines and processes. OPC-UA defines a generic object model and each object can be associated with data type, timestamp, data quality and current value and they can have a hierarchy. Every kind of device, function, and system information can be described using this meta model.

AWS services that ease data access at the factory

AWS Greengrass is an open source edge software which integrates to AWS Cloud. It enables local processing, messaging, Machine Learning (ML) inference, device mesh and many pre-baked software components for speed up application development.

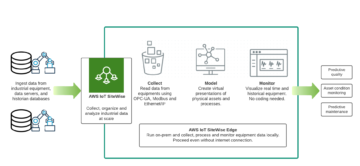

AWS Sitewise is a cloud service for collecting and analyzing data from factory environments. It provides Greengrass compatible edge components for example for data collection from OPC-UA server and for streaming data to AWS Sitewise. Sitewise has a built in time-series database, data modeling capabilities, API layer and portal, which can be deployed and run at the edge as well (which is amazing!).

The AWS Sitewise asset and data modeling is for making a virtual presentation of industrial equipment or process. Data model supports hierarchies, metrics and real time calculations, for example for calculating OEE (Overall Equipment Effectiveness). Each asset is enforced to use data mode that validates incoming data and schema.

Why industrial use cases with AWS?

I prefer more hands-on work than reading Gartner papers; anyhow AWS has been named as a Leader for the eleventh consecutive year and has secured the highest and furthest position on the ability to execute and completeness of vision axes in the 2021 Magic Quadrant for Cloud Infrastructure and Platform Services. It’s very nice to see how AWS is taking industrial solutions seriously and packaging those to a model that is easy to take in use for building digital services to the factory floor and cloud.

1. AWS Sitewise – The power of data model, ingest, analyze and visualize

Sitewise packages nice features which I feel are the greatest are the data and asset modeling, near real time metric calculations (even on edge), visualization and build in time series database. Sitewise is nicely supported by CloudFormation, so you can automate the deployment and even build data models according to your OPC-UA data model automatically (Meta driven Industry standard data model). The Fact that there are edge processing and monitoring capabilities with a portal available makes the Sitewise a really competitive package.

2. AWS Greengrass – Edge computing and secure cloud integration

Speeds up edge application development with public components, like the OPC-UA collector, StreamManager and Kinesis Firehose publisher. The latest Greengrass version 2.x has evolved and has lots of great features. You can provision and run a solution on real hardware or simulate on an EC2 instance or Docker, as you wish. One way to provision Greengrass devices to AWS cloud is to use IoT Fleet Provisioning, where certificates for the device are created on the first connection attempt to the cloud. Applications are easy to deploy from cloud IoT Core to edge Greengrass instances. You can also run serverless AWS Lambdas at the edge, which is really superb! All in all, the complete Greengrass 2.0 package will speed up development.

3. Cloud and Edge – Extra layer of Security

SItewise and Greengrass use AWS IoT Core security features, like certificate based authentication, IoT policies, TLS 1.2 on transport and device defender, which brings the security to a new level. It’s also possible to use custom Certificate Authorities (CA) to issue edge device certificates. Custom CA’s can be stored in AWS CloudHSM and AWS Certificate Manager. Now I can really say that security is our best friend.

4. Agile integration to other solutions

Easy way for integrating data to other solutions is to use Sitewise Edge and Cloud APIs. If you deploy Sitewise to the edge the API is usable there as well, and you can use the data for other factory systems, like MES (Manufacturing Execution System). At least I think this will combine the IT and OT worlds like never before.

5. AutoML for Edge computing

AutoML is for people like me and citizen data scientists, something that will speed up business insights when creating a lot of notebooks or python code is not needed anymore.

These AutoML services are used to organize, track and compare Machine Learning training. When auto deploy is turned on the best model from the experiment is deployed to the endpoint and the best model is automatically selected using the Bandit algorithm. Besides these Amazon SageMaker model monitor will continuously monitor the quality of your machine learning models in real time and I can focus on talking with people and not only machines.

Stay tuned for more

I think that AWS is making it easier to combine cloud workloads with edge computing. Stay tuned for the next blog post where we dig more into the cloud side of this, including Sitewise, Asset and data model, visualization and alarms. And please take a look at the “Predictive maintenance data kickstart” if you haven’t yet:

https://www.solita.fi/en/solita-connected/